Quality Control Process Flowchart

How to draw a quality control process flowchart and present the procedure visually? Read about this major introduction on quality control and view the flowchart examples to help you start.

What is Quality Control Process?

Quality control is a process intended to ensure that product quality or performed service adheres to a defined set of criteria or meets the requirements of the client. Through the quality control process, the product quality will be maintained, and the manufacturing defects will be examined and refined.

The quality control process is divided into three separate processes, which are IQC (incoming quality control), IPQC (in-process quality control) and OQC (outgoing quality control).

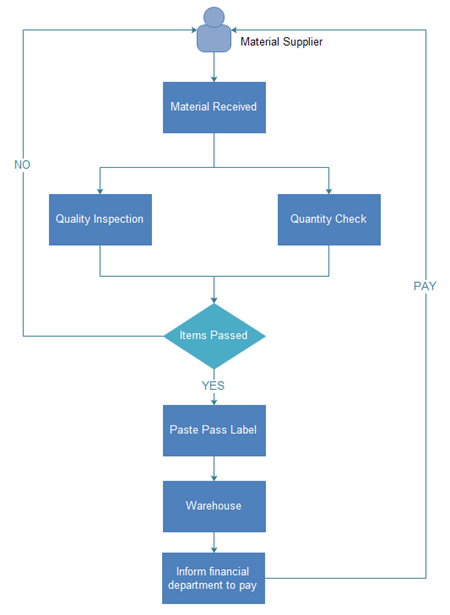

IQC - Incoming Quality Control

Incoming quality control is the process to inspect the raw and component materials from suppliers upon arrival. When detective parts are found, you need to negotiate with the supplier for return or exchange, and the final purpose is to make sure your product quality will not be affected. Below is a sample flowchart of the IQC process.

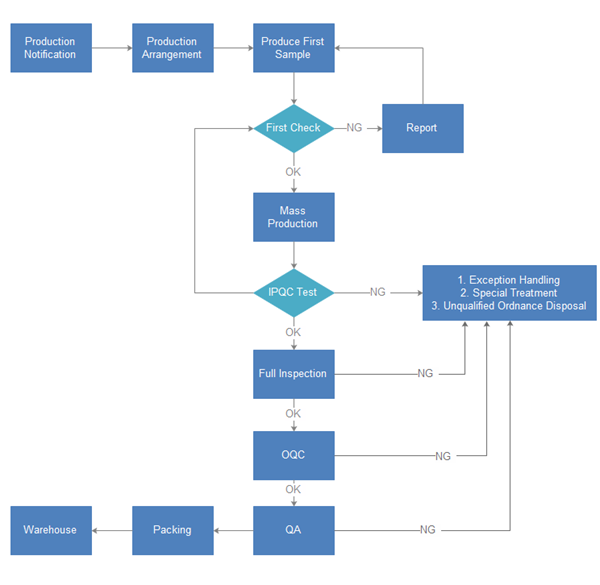

IPQC - In-process Quality Control

IPQC refers to the quality control during the assembly process. It is very important because you can detect and handle the problem that occurs ahead of time.

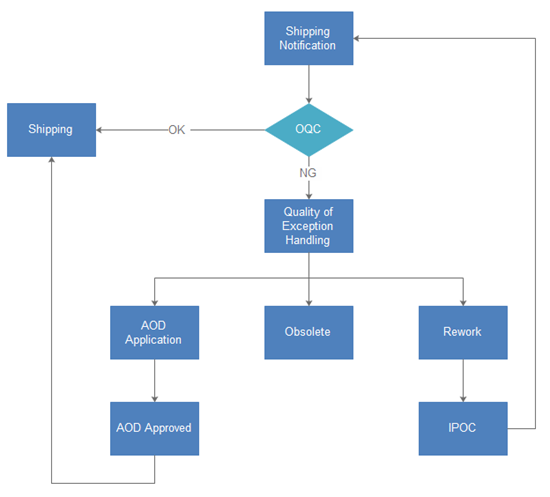

OQC - Outgoing Quality Control

OQA is the inspection of products before shipping. It's a crucial step in ensuring the shipment is defect-free.

评论

发表评论